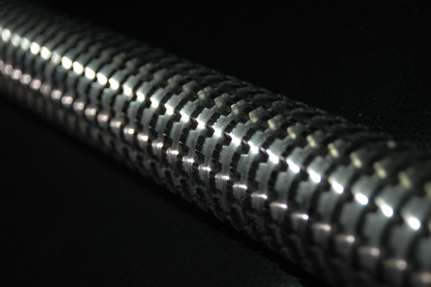

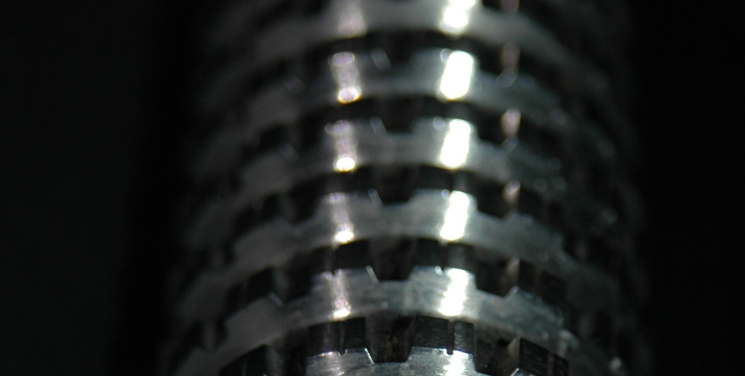

When complex holes or surfaces are to be produced, broaching can be a suitable process in order to achieve high accuracy. Broaches are long tools that can create complex shapes in one pass, containing roughing teeth, semi-finishing teeth and finishing teeth on the same tool. This means the broaches themselves consist of many teeth, with each tooth only cutting once per part. This allows the broach to produce a large number of parts before needing re-sharpening.

High-Speed Steels for Broaches

Broaching can be both internal or external. Internal broaches generally create complex shapes of holes in the centre of tools such as non-circular holes, internal splines, keyways and flat surfaces. External broaches can be used to produce splines, slots or other surface contours that need high accuracy. Broaches are used together with a broaching machine which ensures good repeatability and a stable process suitable for large batch production as an alternative to milling, boring, turning, grinding and EDM.

Depending on the material cut, the complexity of the shape and the amount of parts being produced the requirements on a broach can be somewhat different. Common for all broaches are that the thermal stability of the material needs to be sufficient and that the tool material maintains the same properties over the whole tool. As the broaches can be relatively long tools, they can be prone to distortions during heat treatment and even during use and this can hurt the accuracy of the result. This has moved a large part of the use today from conventional High-Speed Steels towards ASP®.

ASP® grades for Broaches

ASP® grades have several key properties that increase the performance of broaches and their manufacturing. Among the important properties are a high grindability and toughness, reducing the amount of unexpected breakages, high wear resistance and good thermal stability. Typical grades used on the market today include ASP® 2023, ASP® 2030 and ASP® 2015.

Broaching application includes:

- round broaches

- flat broaches

- profiled broaches

| Grades | Applications | Strengths |

|---|---|---|

| Round, flat and profiled broaches | Powder Metallurgy grade when high wear resistance and hardness is needed | |

| Round, flat and profiled broaches | 67 HRC Powder Metallurgy grade with Co. | |

| ASP® 2023 | Round, flat and profiled broaches | Standard 66 HRC Powder Metallurgy grade for broaches |

| Round, flat and profiled broaches | Standard Powder Metallurgy grade for broaching applications in aerospace | |

| Evoloop® M35 | Broaches | Standard High-Speed Steel grade for broaches |