Fine blanking is a high precision metal forming process used in the automotive, heavy duty, electronics, medical, lawn and garden, and general industries.

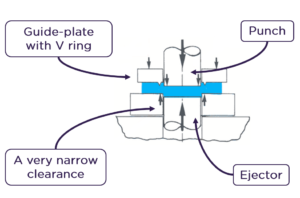

In fine blanking, the strip is held securely by the blank holder (guide-plate with V ring) which forces the metal sheet to stay completely flat while the part is being cut.

The end result is that the produced part has right angles and very tight dimensional tolerances, excellent flatness, and with very little variation from part-to-part throughout long production runs. Fine blankling eliminates machining and reduces secondary operations.

Fine Blanking process

In fine blanking, the produced pieces usually have complex shapes that induce stress raisers to active parts Therefore, punches and dies has to stand very high stresses leading to higher risk of:

- Chipping and cracking: both cracks initiation and cracks growth are deleted by high tool steel ductility/toughness. The very fine and homogeneous Powder Metallurgy tool steel microstructure gives to the tools the good level of impact strength and fatigue limit in case of brittle behavior.

- Excessive wear: abrasion appears on the sliding contacts between the tool and the working material. Abrasive wear is caused by hard particles in contact with the tool surface. The critical tool steel properties are hardness, high volume of carbides and high hardness of the carbides.

- Galling and adhesive wear: Both galling and adhesive wear are created by compressive stresses and sliding contact resulting in heavy friction and locally high temperature which can lead to micro-welds spots that destroy the surface quality of the tool. Then, due to the working stresses, parts of stick material are pulled out of the tool surface by the work material. The critical parameters are roughness, friction coefficient, toughness/ductility and hardness. The tool steel grade has a big influence and Powder Metallurgy tool steels can offer the suitable solution, together with surface coating in order to optimize the sliding properties.

- Plastic deformation: the permanent deformation occurs when the compression stress exceed the compressive yield strength of the tool steel. Hardness is the critical parameter.

- the strength

- the thickness

- design features (sharp radius, complex shapes,…)

- number of part to be produced

These failure mechanisms also depend on the choice of the tool steel and on the quality surface of the tool.

High-Speed Steels solutions

Advanced tooling materials such as Powder Metallurgy tool steels produced by Erasteel (ASP® grades) designed for cold work application can meet very high properties requirements to ensure the good performance of the tools.

Thanks to the very fine Powder Metallurgy (ASP®) microstructure and its high cleanliness (low level of non-metallic inclusions), a lower tooling breakage and maintenance is possible when using the right ASP® tool steel, the ones that can give high hardness, high toughness and the right balance of hard carbides evenly distributed in the matrix.

Within the Erasteel Powder Metallurgy production program, the following tools steels are successfully used in fine blanking application :