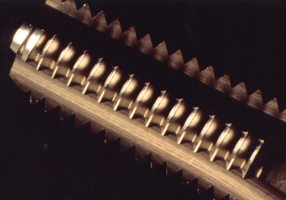

Tapping, thread cutting or thread forming operations are common machining operations, which produce internal thread in drilled holes, mostly to allow the usage of fasteners. Dies are tools used to cut or form outer threads on round stock

High-Speed Steels for tapping

Tapping is a relatively simple machining operation, but if it fails it can have large effects on productivity and part cost. This is due to the fact that tapping is usually one of the last operations performed on a part, and that it can be very difficult to remove a broken tap stuck in a hole. This increases the need for a reliable tool with a very predictable tool life, and is one of many reasons why ASP®, with its high cleanliness, is a great choice for taps.

The powder metallurgical route of producing High-Speed Steels has brought many improvements to tap users and manufacturers. As mentioned above, the increased cleanliness has greatly increased the reliability of taps and reduced the number of early sudden failures. The small spherical and homogeneously dispersed carbides in ASP® has increased the grindability of taps, which makes up a large portion of the manufacturing cost, effectively reducing production costs of taps. The powder metallurgical route also allows of highly alloyed grades giving some ASP® grades the ability to machine hard and difficult materials used in the aerospace industry, such as titanium and nickel alloys

Applications and grades

Thread cutting and forming applications include:

- taps for blind and through holes

- thread forming taps

- thread milling cutters

- threading dies

BlueTap® Co is a great alternative for more price sensitive taps, as it is a true intermediate between conventionally made Evoloop® M35 and ASP®. The important benefits of increased grindability and reliability are kept.